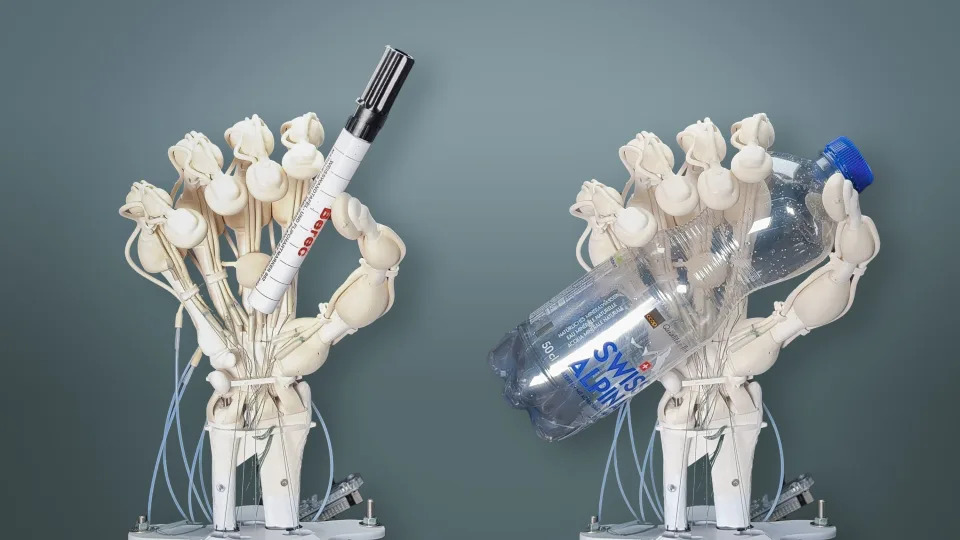

Scientists at ETH Public University in Zurich, in collaboration with the US startup Inkbit, have achieved a groundbreaking feat by successfully 3D printing a robot hand, complete with bones, ligaments, and tendons. This achievement represents a significant advancement in 3D printing technology, with the noteworthy aspect being that the different components of the hand were printed simultaneously rather than assembled afterward, as detailed in a research journal published in Nature.

The robotic hand’s various components were crafted from diverse polymers with varying softness and rigidity, employing a novel laser-scanning technique. This method enables 3D printers to produce “special plastics with elastic qualities” in a single printing process. This breakthrough not only holds promise for the rapidly evolving field of prosthetics but also extends to any domain requiring the fabrication of soft robotic structures.

In essence, the researchers at Inkbit have pioneered a technique for 3D printing slow-curing plastics, a departure from the conventional use of fast-curing plastics. This hybrid printing approach offers various advantages over standard fast-cure projects, including heightened durability and improved elastic properties. Moreover, this technology enables a more accurate emulation of natural structures, as demonstrated in the aforementioned creation of a robotic hand.

According to robotics professor Robert Katzschmann from ETH Zurich, “Robots constructed from soft materials, like the hand we developed, offer advantages over traditional metal robots. Their soft nature reduces the risk of injury when working with humans, and they are better suited for handling delicate objects.

This advancement maintains a layer-by-layer printing process, but with a built-in scanner continuously monitoring the surface for irregularities, instructing the system to progress to the next material type. Moreover, updates to the extruder and scraper now allow the utilization of slow-curing polymers, providing the flexibility to fine-tune stiffness for crafting distinct objects suitable for various industries. While creating human-like appendages is one application, manufacturing items that absorb noise and vibrations is another.

Inkbit, a startup affiliated with MIT, played a pivotal role in developing this technology and is actively exploring commercial opportunities. The company plans to offer these newly developed printers to manufacturers and also intends to market intricate 3D-printed objects utilizing this technology to smaller entities.