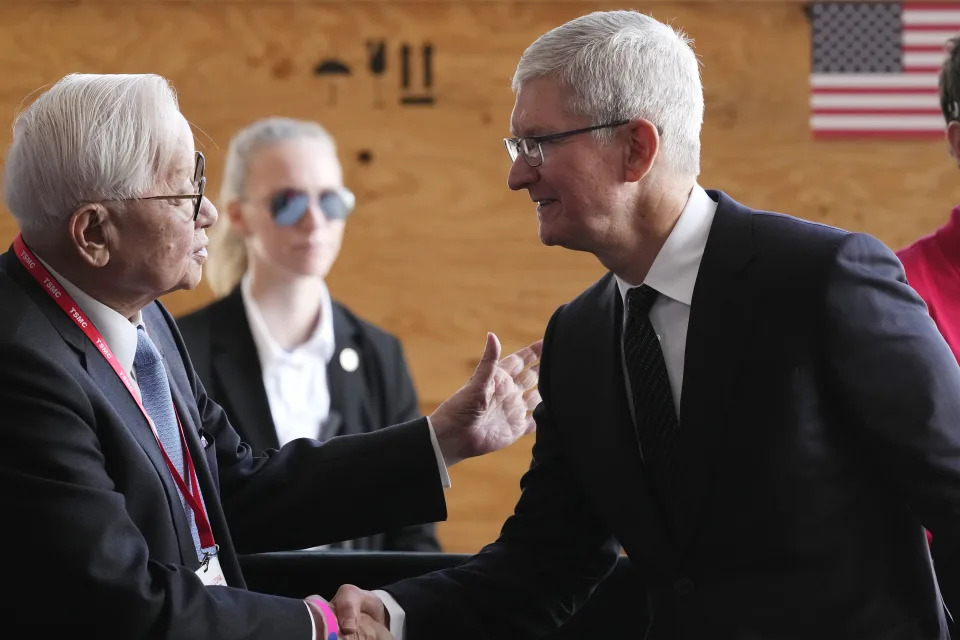

Apple announced that it will be buying chips for its iPhones, Macs, and other key products made in Taiwan Semiconductor Manufacturing Company’s (TSMC) new factory in Phoenix, Arizona. This was seen as a win for the US government, which wants to boost manufacturing in the US and lessen its reliance on overseas suppliers.

However, a new report by The Information says that even though the components for Apple’s chips will be manufactured in the US, they’ll still have to be sent back to TSMC’s home country in Taiwan for assembly.

This is because TSMC’s factory in Arizona doesn’t have the facilities to package the company’s more advanced chips. Packaging is the final stage of fabrication, wherein the chip’s components are assembled inside a housing as close together as possible to enhance speed and power efficiency.

Apple is currently the only customer using TSMC’s packaging method at high volumes, but TSMC has other clients, including NVIDIA, AMD, and Tesla. It’s unclear how many of those companies’ chip models will have to be sent back to Taiwan for packaging, but they reportedly include chips for artificial intelligence, including NVIDIA’s H100.

The US government has set aside over $50 billion in funding under the CHIPS Act to provide subsidies for companies building chip factories in the US. The government is also encouraging the growth of the US semiconductor industry to mitigate fallout from the growing tension between the United States and China over Taiwan.

However, the government is only providing $2.5 billion in funding for chip packaging under the CHIPS Act. This suggests that the government is not prioritizing packaging as much as manufacturing.

TSMC has no plans to build packaging facilities in the US due to the huge costs involved. Any future packaging method it develops will most likely be offered in Taiwan.

Here are some additional thoughts on the matter:

The report by The Information highlights the challenges that the US faces in its efforts to boost its semiconductor industry and reduce its reliance on overseas suppliers. Packaging is a critical part of the chip manufacturing process, and the fact that the US does not have the capability to package its own advanced chips is a significant disadvantage.

The US government’s decision to prioritize manufacturing over packaging is understandable. Manufacturing is the more capital-intensive part of the chipmaking process, and it is also the area where the US is most reliant on overseas suppliers. However, the government should not neglect packaging entirely. If the US wants to have a truly self-sufficient semiconductor industry, it needs to invest in both manufacturing and packaging.

TSMC’s decision not to build packaging facilities in the US is also understandable. The company has already invested heavily in its packaging facilities in Taiwan, and it would be very costly to replicate that investment in the US. However, TSMC’s decision could have implications for US tech companies that rely on TSMC for their chips. If TSMC does not build packaging facilities in the US, those companies may be forced to send their chips to Taiwan for packaging, which could add to their costs and lead to longer lead times.

Overall, the report by The Information is a sobering reminder of the challenges that the US faces in its efforts to boost its semiconductor industry. The US government and US tech companies need to work together to address these challenges if the US wants to remain a leader in the global semiconductor market.